Medical Waste Sterilization vs. Disinfection

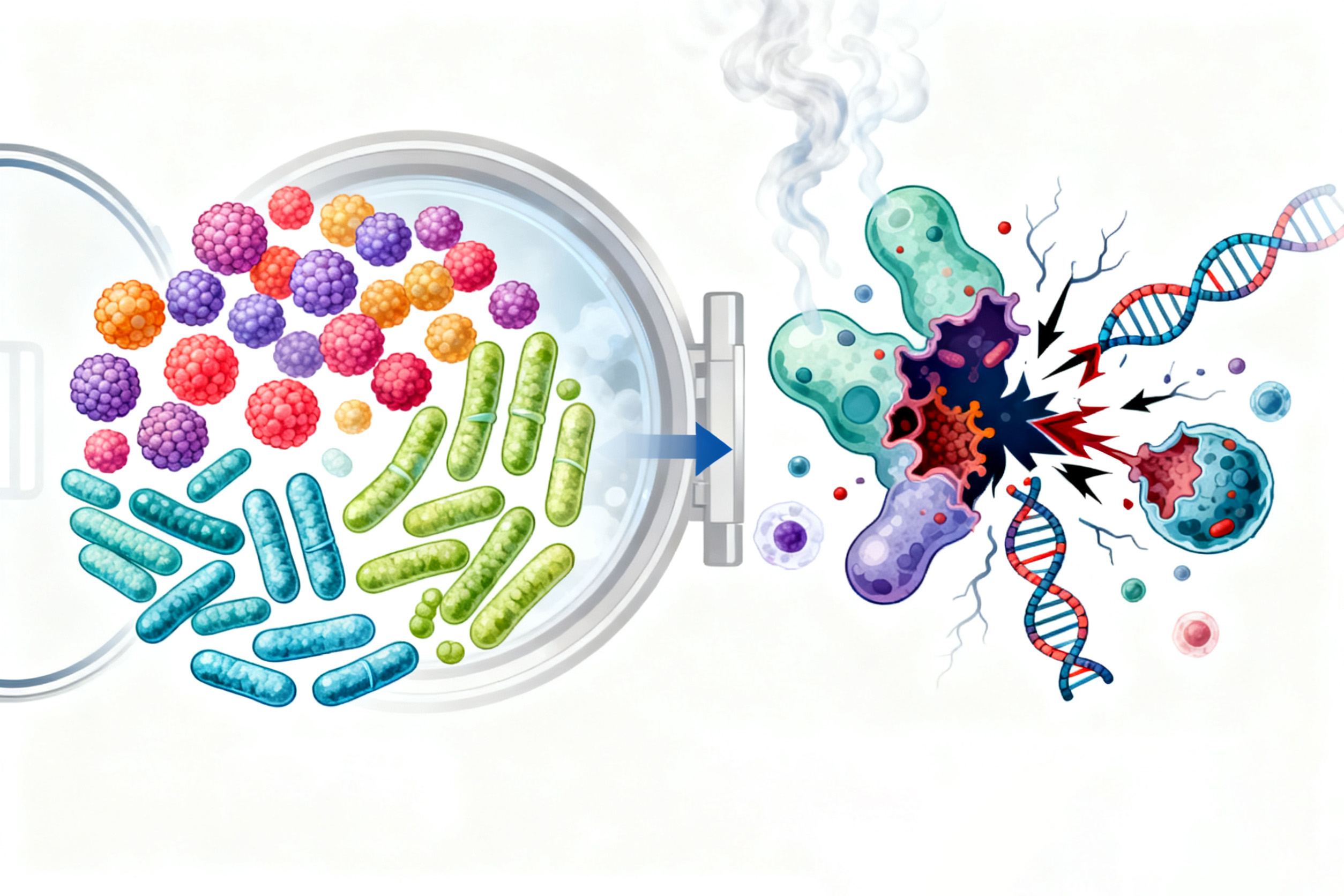

Medical waste is dangerous because it often contains infectious materials such as blood, sharps, and contaminated plastics. To make this waste safe, it must be either sterilized or disinfected. While the two terms are sometimes used interchangeably, they are very different in practice — and the difference directly affects safety, sustainability, and recycling.

What is Sterilization?

Definition: Sterilization eliminates all forms of life — bacteria, viruses, fungi, and even highly resistant spores.

Assurance level: Validated to a Sterility Assurance Level (SAL) of 10⁻⁶, meaning less than one chance in a million that a single microorganism survives.

But SAL 10⁻⁶ is not the full story. The type of test spore used to validate the process matters:

| Sterilization Technology | Biological Indicator (Test Spore) | Why It Matters |

| Steam Sterilization (Autoclave, moist heat) | Geobacillus stearothermophilus spores | These spores are highly resistant to moist heat. If an autoclave can kill them, it can reliably sterilize all other pathogens. |

| Dry Heat Sterilization (hot air, no moisture) | Bacillus atrophaeus spores | These spores are resistant to dry heat. Used to validate hot-air or chemical sterilization methods. |

When sterilization is proven against the most resistant spores for that method, safety is guaranteed. Autoclaves (steam sterilization) validated with G. stearothermophilus spores provide the highest assurance of sterilization for medical waste.

What is Disinfection?

Definition: Disinfection reduces microorganisms but does not necessarily kill them all.

Limitations: Spores and some pathogens may survive.

Use: Suitable for surface cleaning or liquid waste. A minimum recommended requirement for general medical waste treatment.

International Criteria of Medical Waste Treatment

The STAATT criteria (State and Territorial Association on Alternative Treatment Technologies) define microbial inactivation levels:

Level I Inactivation of vegetative bacteria, fungi, and lipophilic viruses at a 6 Log10 reduction or greater

Level II Inactivation of vegetative bacteria, fungi, lipophilic/hydrophilic viruses, parasites, and mycobacteria at a 6 Log10 reduction or greater

Level III Inactivation of vegetative bacteria, fungi, lipophilic/hydrophilic viruses, parasites, and mycobacteria at a 6 Log10 reduction or greater; and inactivation of B. stearothermophilus spores (Geobacillus stearothermophilus spores) and B. subtilis spores (Bacillus atrophaeus spores) at a 4 Log10 reduction or greater

Level IV Inactivation of vegetative bacteria, fungi, lipophilic/hydrophilic viruses, parasites, and mycobacteria, and B. stearothermophilus spores (Geobacillus stearothermophilus spores) at a 6 Log10 reduction or greater

Level III disinfection has been the recommended minimum criteria by STAATT.

STAATT Levels Achieved by Common Technologies

| Technology | Typical Operating Temperature | STAATT Level | Biological Indicator (Test Spore) | Explanation |

| Autoclave (Steam Sterilization, High Vacuum) | 121–134 °C (pressurized steam) | Level IV (Sterilization) | Geobacillus stearothermophilus | Gold standard for moist-heat sterilization. Proven SAL 10⁻⁶, complete inactivation of all microorganisms including resistant spores. |

| Integrated Autoclave with Shredder Systems | 121–134 °C (pressurized steam) | Level IV (Sterilization) | Geobacillus stearothermophilus | Same sterilization assurance as autoclave, with shredding for volume reduction and recycling. |

| Dry Heat Sterilization (frictional, hot air) | 120–150 °C | Level III–IV (depending on validation) | Bacillus atrophaeus Geobacillus stearothermophilus | Can achieve sterilization if evenly heated and properly validated, but less reliable than steam. |

| Microwave Disinfection | 95–100 °C (mainly by heating internal or injected moisture) | Level II–III (Disinfection) | Bacillus atrophaeus | Heats moisture in waste, but not validated with resistant spores. Classified as disinfection, not sterilization. |

| Chemical Disinfection | Ambient or slightly elevated | Level II–III (Disinfection) | None standardized for spores | Effective for liquid waste, but does not assure sterilization of solids or spores. |

| Plasma Arc | >3,000 °C (plasma torch) | Level IV (Sterilization) | Not spore-based; destroys all organic matter | Extremely high temperatures gasify waste, achieving complete destruction. High cost, niche use. |

Only autoclaves are the common used technologies to reliable achieve STAATT Level IV sterilization and SAL-6 (6log10), validated with G. stearothermophilus spores.

Why Microwave is Not Sterilization

Microwave systems are sometimes misunderstood as “sterilization,” but in reality they are disinfection technologies.

How microwaves work

Microwaves usually do not directly kill germs. Instead, they mainly heat the moisture inside the waste (or extra moisture injected into the system). The hot environment can kill many bacteria and viruses, but it is not the same as the temperature controlled in pressurized steam sterilization.

Not the right spores for validation

Microwave systems use Bacillus atrophaeus spores for testing, however, these are used for dry heat. In a moist processing environment. 6log10 (99.9999%) of Bacillus atrophaeus spores does not validate SAL 10⁻⁶ of sterilization assurance. That means microwaves cannot scientifically prove sterilization at the required.

Industry recognition

In the medical industry worldwide, microwave systems are not validated or accepted as a sterilization technology.

Why Autoclave Sterilization is Safer

Proven by the toughest spores (G. stearothermophilus), not just easy-to-kill organisms.

Complete safety: eliminates all pathogens, including HIV, hepatitis, TB, and COVID-19.

No toxic emissions: unlike incineration.

Cost-effective: cost-effective in operation and maintenance.

Enables recycling: sterilized plastics and other materials can be safely recycled.

Globally compliant: meets WHO, EU, and EPA standards.

Advanced: The modern medical waste autoclave system efficiently solve most of the problems in medical waste world.

At Gient, our first priority is protecting people and the planet. We are dedicated to the highest standards of safety and sustainability in every solution we deliver.